A Symphony of Springs: Diagnosing and Correcting Temporal Drift

There's a quiet dignity to antique adding machines. More than just calculating devices, they are testaments to an era when mechanical ingenuity reigned supreme, when the precision of a gear and the resilience of a spring were valued as much as the result they produced. Holding one in your hands – a Brunsviga, a Marchant, a Friden – isn't merely touching a machine; it’s connecting with the hands of the craftsman who meticulously assembled it, the clerks who relied on its accuracy, and the echoes of countless calculations that shaped the modern world.

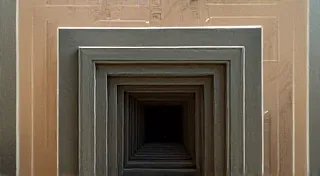

I recall my first encounter with a Brunsviga, a rather imposing machine with its distinctive stepped drums. It was rescued from a dusty attic, coated in grime and seemingly lifeless. But beneath the neglect, I sensed a story waiting to be rediscovered. It was then I began to appreciate the complexity of these machines, not just as tools, but as intricate works of mechanical art. And it was then that I learned about “temporal drift” – a peculiar phenomenon where, over decades of use (or even simply the passage of time), the accuracy of an adding machine can subtly degrade.

Understanding Temporal Drift: The Enemy of Accuracy

Temporal drift isn't a catastrophic failure. It’s a gradual, almost imperceptible degradation in accuracy. It's the consequence of countless tiny movements, the subtle deformation of springs under constant tension, the microscopic wear on escapement mechanisms. Think of it like the slow creep of rust on metal, or the gradual bending of a wooden beam under consistent weight. It’s a process that, unchecked, leads to increasingly inaccurate results.

Several factors contribute to this drift. The most common are: the loss of elasticity in springs (they become fatigued and don't return to their original form as reliably), slight dimensional changes in metal components due to temperature fluctuations and humidity, and the accumulation of microscopic debris that interferes with the smooth operation of the mechanisms. Even the lubricants originally used – often thick greases – can degrade over time, gumming up the works and exacerbating the problem. Another important consideration is the effect of corrosion; even seemingly minor surface oxidation can alter frictional characteristics.

Diagnosing the Problem: A Detective's Approach

Diagnosing temporal drift requires patience and a keen eye for detail. It's less about finding a single broken part and more about identifying the subtle inconsistencies that are contributing to the inaccuracy. Begin by running a series of test calculations. Start with simple additions and subtractions, then progress to more complex sequences. Carefully note the discrepancies. Are they consistent? Do they appear to worsen with longer calculations?

Next, meticulously examine each key component. The carry mechanism is a prime suspect. These levers and pawls are responsible for transferring the accumulated total from one column to the next, and they are particularly vulnerable to wear and dirt. The escapement, the heart of the adding machine’s operation, is another critical area to scrutinize. It’s responsible for regulating the movement of the totalizers and ensuring that each digit is accurately registered.

Don't overlook the seemingly minor details. Check the tension of the key levers. Are they all operating with equal resistance? Examine the pinions (the small gears that mesh with the totalizers) for signs of wear or damage. Even the condition of the platen (the roller used for printing the results) can influence accuracy, particularly if the impression is uneven.

Corrective Measures: Recalibrating the Symphony

Correcting temporal drift isn’t about replacing parts wholesale. It’s about restoring the machine to its original mechanical harmony. In many cases, a thorough cleaning and lubrication can work wonders. Use a specialized cleaning solvent designed for delicate machinery, and avoid harsh chemicals that can damage the metal or rubber components. Lubrication should be targeted and minimal; a light, synthetic oil is preferable to thick grease.

If cleaning and lubrication don’t fully address the problem, more targeted adjustments may be necessary. Many antique adding machines have adjustable elements that allow for fine-tuning of the mechanism. For example, the tension of the carry levers can often be adjusted to compensate for slight dimensional changes or wear. Similarly, the escapement mechanism may have adjustable screws or levers that can be used to optimize its timing.

In some cases, minor repairs may be required. A worn carry lever can be replaced, a damaged pinion can be repaired or substituted, and a loose screw can be tightened. However, always exercise caution and avoid making irreversible modifications. Remember, the goal is to restore the machine to its original functionality, not to create a new invention.

When dealing with escapement adjustments, proceed with extreme care. These mechanisms are incredibly sensitive, and even a slight misadjustment can significantly impact accuracy. Refer to the original manufacturer’s documentation if available, or consult with an experienced antique adding machine technician.

The Reward: A Machine Reborn

Restoring an antique adding machine and correcting its temporal drift is a labor of love. It requires patience, skill, and a deep appreciation for the craftsmanship of a bygone era. But the reward is immeasurable. To witness a machine, once silent and inaccurate, come back to life, performing calculations with the precision it was originally designed for – that is a truly satisfying experience. It’s a connection to history, a testament to human ingenuity, and a celebration of the enduring beauty of mechanical devices. The clicking and whirring sounds become more than just noises; they become the symphony of springs, a mechanical ballad of precision and resilience.

These machines weren't just built to calculate; they were built to last. And with a little care and attention, they can continue to do so for generations to come.