The Geometry of Precision: A Study in Engineering Elegance

There's a particular scent that clings to antique adding machines – a subtle blend of aged metal, dried oil, and the ghosts of countless calculations. It’s a scent that transports me back, not to my own life necessarily, but to a time of quiet diligence, of focused labor, and a deep respect for the tools of the trade. These machines, often overlooked in our digital age, represent far more than mere calculators; they are testaments to a unique blend of artistry, engineering ingenuity, and the relentless pursuit of mechanical precision. They are, quite simply, beautiful.

My fascination began years ago, in a dusty corner of my grandfather’s workshop. He was a bookkeeper, a man of numbers and order. Amidst the scattered tools and half-finished projects, sat a Brunswicker adding machine – a majestic presence of brass and steel. He didn’t talk much about it, but I remember the quiet satisfaction he took in its operation, the rhythmic clicks and whirs a comforting soundtrack to his workday. It wasn’t just a tool for him; it was a companion, a reliable friend in a world that demanded accuracy and dependability. It sparked in me an appreciation for a world of complex mechanics, a tangible connection to a bygone era.

The Dawn of Mechanical Calculation

The history of adding machines is fascinating. While rudimentary mechanical aids for calculation existed for centuries, the true emergence of the modern adding machine came in the 19th century. Figures like Charles Xavier Thomas, with his Thomas Arithmometer (1822), laid the groundwork. The Arithmometer, initially met with skepticism, gradually gained acceptance and became the standard for many years. Then followed others – Odhner, Friden, Marchant – each refining the design, improving efficiency, and pushing the boundaries of what was mechanically possible. These machines weren't born from the desire to make things 'easier,' but from a profound need for accuracy in commerce and industry.

Before the widespread adoption of electric calculators and computers, adding machines were integral to businesses of all sizes. From bookkeeping to payroll, these machines powered the engine of the industrial age. They represented a commitment to precision – a signal to clients and colleagues that a business valued accuracy and meticulousness. The design reflected that value. Every component, every lever and gear, was painstakingly crafted and assembled.

A Symphony of Gears and Levers

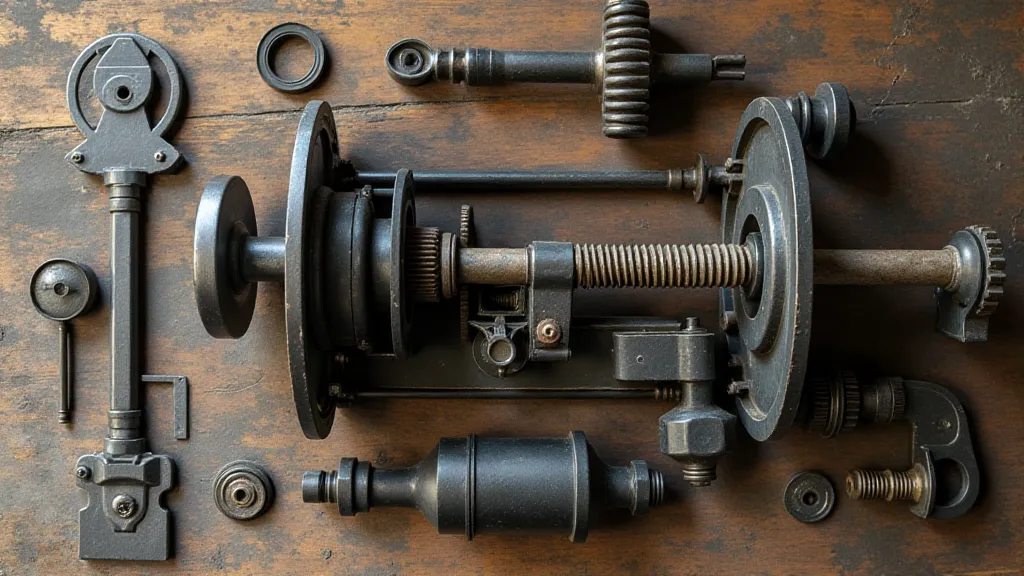

The internal mechanisms of antique adding machines are truly remarkable. Consider the Brunswicker, for example. It utilizes a system of numbered stepped drums – each representing a digit – which are engaged by a complex network of levers and clutches. The operator presses a key corresponding to the digit being added, and a corresponding lever engages the appropriate drum, advancing it by the correct amount. The visual complexity can be daunting at first glance, but the underlying logic is surprisingly elegant.

Other designs, like the Odhner, employed a different approach, using a rotating cylindrical drum and a system of oscillating levers. The Friden machines, developed much later, used a more compact and efficient design based on a "carry mechanism." Regardless of the specific implementation, each machine shared a common thread: a meticulous attention to detail and a deep understanding of mechanical principles. The tolerances were incredibly tight. A fraction of a millimeter could render the machine useless.

The manufacturing process was equally impressive. While mass production in the modern sense wasn't possible, skilled machinists and craftsmen painstakingly fabricated each component. Gears were cut with precision tools, levers were shaped with care, and each part was meticulously polished and finished. The quality of the materials used – primarily brass, steel, and occasionally bronze – contributed to the machines’ durability and longevity. These were not disposable devices; they were built to last.

The Art of Restoration – A Labour of Love

Restoring antique adding machines is a delicate and rewarding process. It's not simply about cleaning and lubricating; it’s about understanding the machine's design, identifying its quirks, and patiently bringing it back to operational condition. The first step is a thorough cleaning – removing years of accumulated grime and debris. Then comes lubrication – a vital step in ensuring smooth operation. The original lubricants were often thick, heavy oils, but modern synthetic oils can often provide superior performance and longevity.

More complex repairs often require specialized tools and skills. Replacing worn gears or levers can be particularly challenging, requiring the ability to precisely fabricate new parts or locate suitable replacements. The process requires a combination of technical knowledge, patience, and a genuine appreciation for the machine's history and craftsmanship. It’s a deeply meditative activity – a chance to connect with the past and to appreciate the ingenuity of the engineers and craftsmen who created these remarkable devices.

It’s crucial to remember that these machines are more than just collections of metal parts. They are embodiments of a particular time and place, reflections of the values and priorities of the era in which they were created. Restoring them is not just about preserving a mechanical device; it’s about preserving a piece of history.

Collecting and Appreciating

Collecting antique adding machines is a fascinating hobby. There's a certain satisfaction in acquiring and preserving these pieces of mechanical history. Different models have different values, based on factors such as rarity, condition, and historical significance. Some of the early Thomas Arithmometers can command considerable prices, while more common models like the Brunswicker and Friden can be found at more accessible levels. The joy, however, lies not solely in the acquisition but in the appreciation – understanding the intricate workings and the legacy of these machines.

Beyond the mechanical elegance, there’s the aesthetic appeal. The brass and steel finishes, the carefully engraved markings, the satisfying click of the keys – all contribute to a sensory experience that is both tactile and visually pleasing. These machines represent a time when function and form were inextricably linked, when beauty was not sacrificed in the name of efficiency.

As we move further into the digital age, these mechanical marvels serve as a powerful reminder of the ingenuity and craftsmanship of the past. They are a testament to the enduring power of mechanical innovation and a tangible link to a time when precision, accuracy, and beauty were paramount. They deserve to be remembered, preserved, and appreciated – not just as machines, but as works of art.